The poultry industry faces everincreasing challenges in optimising production efficiency while keeping costs under control. Among the critical factors influencing profitability, dietary energy stands out as a major component. Due to their high energy density, fats and oils are commonly added in broiler diets to meet energy requirements.

However, ensuring efficient fat utilisation poses a significant challenge due to the complexity of the digestion process. The absorption and digestion of fats in broilers relies on emulsification, a process where fats are broken down into smaller droplets to be further accessed by lipolytic enzymes. Emulsification is facilitated by endogenous emulsifiers, such as bile salts. The ever increased energy intake on one hand and the limitations in bile and enzyme activity on the other, in particular in young broilers, somewhat compromises fat utilisation during it.

SUMMARY

- Optimising the utilisation of dietary fat/oil has never been more critical for cost-effective production in the poultry industry.

- Different dietary emulsifiers exhibit greatly different Hydrophilic-Lipophilic Balance (HLB) values.

- Different bio-emulsifier lysolecithins based also exhibit varying degrees of HLB values, which can determine their performance.

- Well-designed bio-emulsifiers must be studied under real production conditions with high level of replication.

- Well-studied bio-emulsifiers must exert several biological benefits beyond just fat-emulsification. Namely, to be able to demonstrate the optimisation of:

- The animals’ own metabolic efficiency.

- Nutrient digestibility.

- Growth performance.

- Meat quality.

- Animal welfare.

- Reduced significantly the overall production cost.

- Exhibit wider immune-metabolic benefits which extend beyond just fat emulsification

The role of emulsifiers in fat digestion

Bile salts are amphipathic molecules, meaning they have both hydrophilic (water-loving) and hydrophobic (fat-loving) regions. This unique property allows bile salts to interact with both water and fat molecules, facilitating the breakdown and dispersion of fats in the watery environment of the digestive tract. Ingested fats are typically in the form of large globules which are insoluble in water and cannot be directly accessed by lipolytic enzymes. Bile salts in the small intestine play a crucial role in emulsification by transforming these large fat globules into smaller droplets and increase the surface area of fats, allowing thus, lipolytic enzymes, such as pancreatic lipase, to efficiently access and digest the fats. During fat digestion, bile salts emulsify fat into smaller droplets, enabling pancreatic lipase to break down triglycerides into fatty acids and monoglycerides. Micelles form around fat molecules, aiding absorption into enterocytes. Inside these cells, reassembly into triglycerides occurs, followed by the formation of chylomicron particles that contain triglycerides, cholesterol, and fatsoluble vitamins. These chylomicrons are released into the lymphatic system, later entering the bloodstream for lipid transport. Chylomicrons deliver their cargo to tissues, where lipoprotein lipase releases fatty acids for energy or storage. Eventually, the liver clears the remaining chylomicrons from the bloodstream.

Hydrolysed lecithins and their functional role

Hydrolysed lecithins, also known as lysolecithins, are naturally formed during the digestion of dietary fats. They play a crucial role in the emulsification of dietary lipids in the intestinal lumen, aiding lipid absorption by creating mixed micelles with bile salts. Additionally, research has shown that lysolecithins can impact cell membranes, influencing their fluidity and permeability. Researchers isolated and characterised lysolecithins by phospholipid hydrolysis in the early 20th century. However, it was only a couple of decades ago when more comprehensive research explored the involvement of lysolecithins in wider cell signalling, inflammation, and immune responses. Notably, lysolecithins have been shown to act as signalling molecules which can affect the production and release of inflammatory mediators. Some studies have even suggested that specific lysolecithins can inhibit the production of pro-inflammatory cytokines, exhibiting anti-inflammatory effects. Furthermore, lysolecithins may influence immune responses by interacting with immune cells. Namely, they can modulate the activation, proliferation, and cytokine production of immune cells, potentially affecting the body’s immune defence mechanisms. Within cells, lysolecithins act as signalling molecules, influencing various cellular processes such as signalling pathways related to cell growth, differentiation, and apoptosis. Some evidence suggests that lysolecithins incorporated into cell membranes may alter their fluidity and permeability. However, it is important to note that the bioactive properties of lysolecithins vary greatly depending on their composition and formulation properties on one hand and on the other hand on the target animal species, and the context of study. Ongoing research in this field will likely reveal further insights into the diverse roles of lysolecithins in biological systems.

Formulating effective bio-emulsifier

Exogenous emulsifiers may boost endogenous bile salts activity, by facilitating the formation of emulsion droplets and the subsequent transformation of fatty acids into micelles. This has the ability to facilitate better access and action of lipases, promoting the hydrolysis of triglycerides into fatty acids and monoglycerides. Several emulsifier categories have been used in poultry nutrition, including soy-lecithins, hydrolysed lecithins and synthetic emulsifiers (E484), all of which exert different Hydrophilic-Lipophilic Balance (HLB). The HLB is a numerical scale by indicating its affinity for water or oil, and as such it determines its emulsifying ability and performance in different applications. The HLB scale ranges from 0 to 20, with lower values indicating a higher affinity for oils (lipophilic) and higher values indicating a higher affinity for water (hydrophilic). Emulsifiers with low HLB values are better suited for creating water in oil (W/O) emulsions, where water droplets are dispersed in a continuous oil phase. Conversely, emulsifiers with high HLB values are more effective in forming oil-in-water (O/W) emulsions, where oil droplets are dispersed in a continuous water phase. The selection of an emulsifier with the appropriate HLB value is crucial for achieving stable emulsions.

Some examples of emulsifiers and their corresponding HLB ranges are as follows:

- Low HLB Emulsifiers (0-7): These emulsifiers are more effective in stabilising water-in-oil (W/O) emulsions. Examples include lecithins (HLB~3) and sorbitan monooleate (HLB~4).

- Intermediate HLB Emulsifiers (7-10): These emulsifiers are well-suited for forming stable oil-in-water (O/W) emulsions, where small droplets of oil are dispersed in a continuous water phase. Examples include sorbitan monostearate and lysolecithins.

- For lysolecithins: The HLB value depends on the degree of hydrolysis and the resulting molecular structure. Different lysolecithin may have varying HLB values due to their unique hydrophilic and lipophilic characteristics. The HLB value of lysolecithin can be crucial in determining its performance as an emulsifier in specific applications, guiding formulators to select the most suitable lysolecithin for achieving the desired emulsification properties.

- High HLB Emulsifiers (10-20): These emulsifiers are better suited for stabilising oil-in-water (O/W) emulsions. Examples include Glyceryl polyethylene glycol ricinolate (E484) and some bile salts.

By carefully selecting emulsifiers with the appropriate HLB value for a specific application, formulators can select emulsifiers with the desired properties. The HLB concept is a valuable tool in emulsion formulation and plays a key role in improving bile salts performances. In this video, the significance of an oil in water emulsion capacity test is explained. This in-vitro test shows that carefully selected bio-emulsifiers with the right HLB value perform significantly better compared to the most commonly emulsifier categories used by the animal nutrition industry. However, living organisms are far more complex than pure chemical emulsions. Moreover, technologies aimed for animal use should be tested under industrial production and not only at well controlled experimental conditions.

Recently, researchers developed a novel system termed COALMINERS (ChrOnic intestinAl infLamMatIoN modEl under realfaRming conditionS) in which mini-wired-pens (high level of replication) are placed inside a commercial facility so that the birds under study have the same cumulative environmental production exposure, where the effects of a new bioemulsifier were investigated.

Experimental design and results

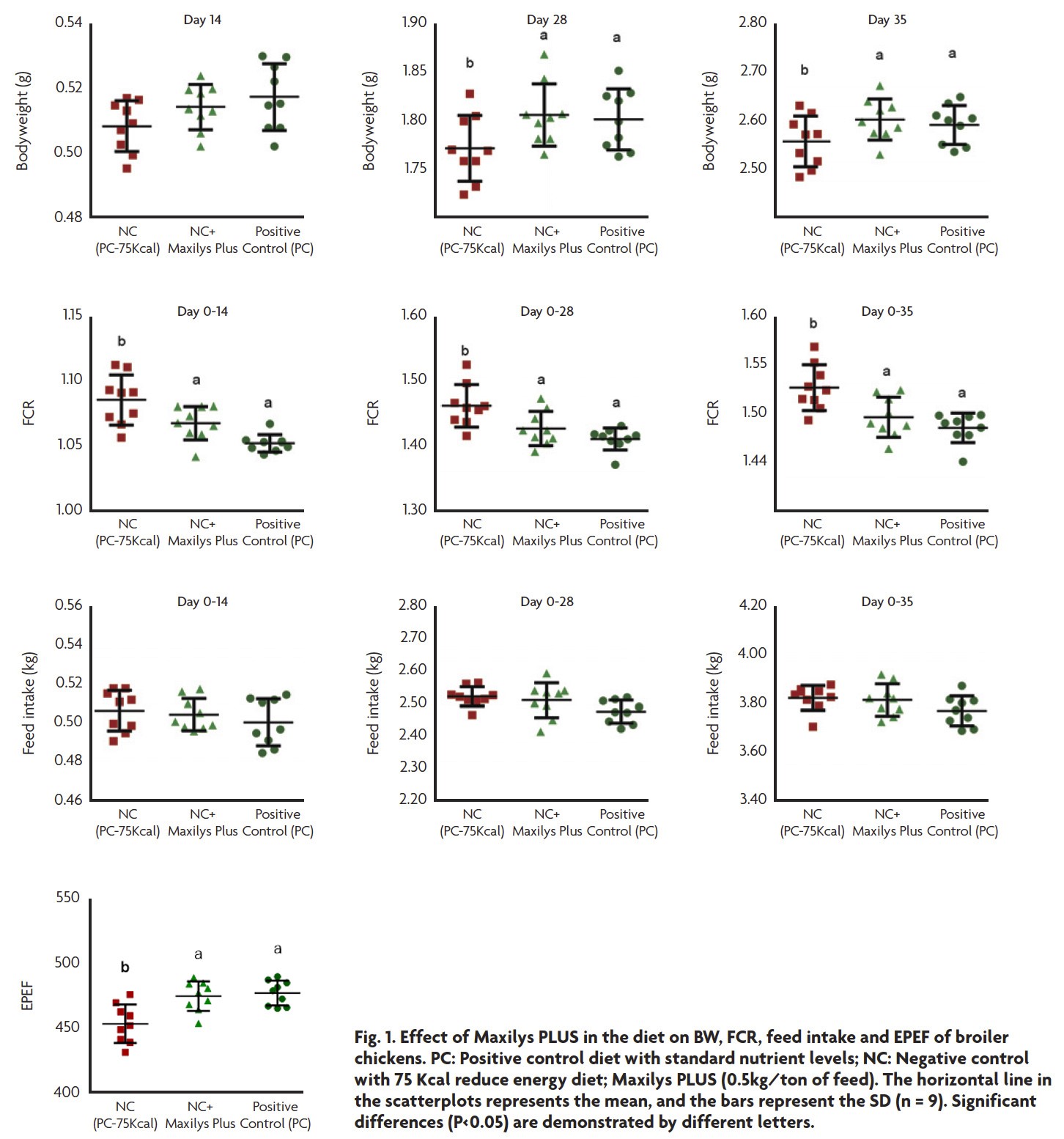

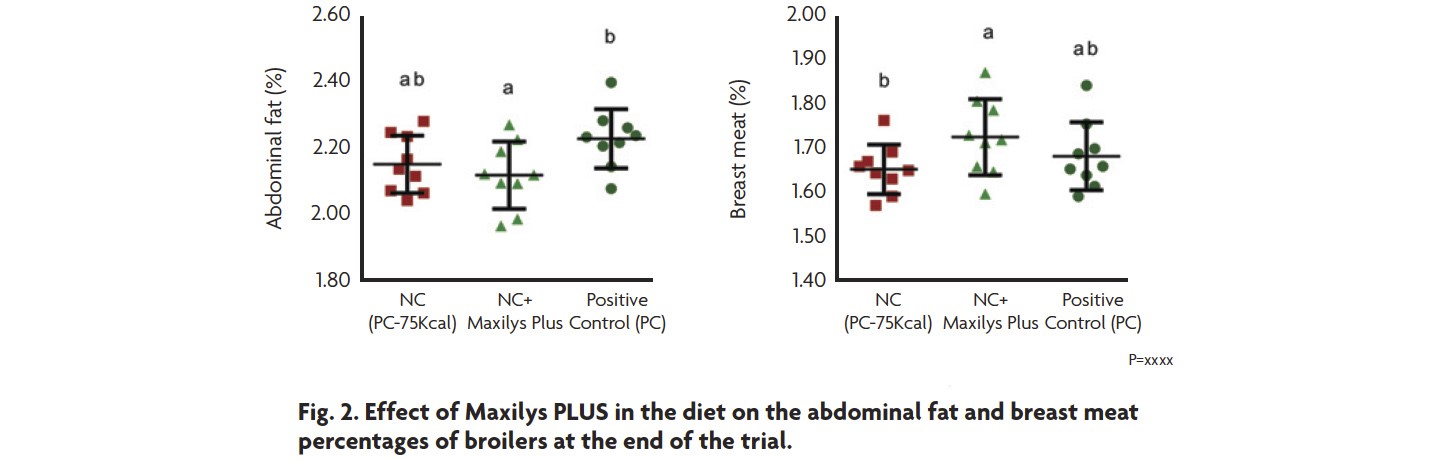

The study involved 720 male broiler chicks (Ross 308) placed on a commercial farm for a five-week feeding trial and divided into three treatments, with nine pens per group: a positive control (PC) with a standard ME value, a negative control (NC) with reduced ME levels (75Kcal/kg feed, lower than PC), and a treatment with the bio-emulsifier added to the NC diet. The results showed that the reformulated diet with reduced ME (NC) negatively impacted growth performance, leading to lower body weight and higher feed conversion ratio (FCR) compared to the PC. However, when Maxilys PLUS was added to the NC diet, the growth performance improved significantly, achieving similar body weight and FCR with the PC treatment. More importantly, the bio-emulsifier improved meat quality by lowering abdominal fat and improving breast protein yield compared to the NC group. Furthermore, the prevalence and severity of footpad lesions were numerically lower in the bio-emulsifier group compared to the NC and PC treatments, indicating potential benefits for animal welfare (Fig. 1).

Economic implications

The addition of bio-emulsifier in the reformulated diet resulted in reduced feed costs (minus $13/Ton of feed), as it replaced part of the expensive soybean oil. This costsaving effect increased the return on investment (ROI) threefold compared to the PC treatment.

Study findings

The findings of this novel study highlight the importance for well-designed bio-emulsifiers that enhance the performance and economic viability of broiler production. Broilers under the new bio-emulsifier exhibited growth performance and feed efficiency comparable to those fed the positive control diet with standard energy levels. The concomitant breast yield improvement and abdominal fat reduction (Fig. 2) demonstrate the capacity of the bioemulsifier not only to enhance nutrient utilisation and support optimal growth under real production conditions, but also to improve nutritionally the produced meat. This was accompanied by significant improvements in animal well-fare as evidenced by the reduction of food pad lesions. At the same time, the bio-emulsifier effectively lowered feed costs by reducing the reliance on costly soybean oil with a substantially increased return on investment (ROI).

In conclusion

The study highlights that well-designed and tested bio-emulsifiers, like Maxilys® Plus in this instance, act beyond fat emulsification and can revolutionise broiler production under real farming conditions. The ability to optimise nutrient digestibility, enhance growth performance and, reduce production costs, coupled with the observed animal welfare benefits, make well-designed and well-studied bio-emulsifiers like Maxilys® Plus valuable assets in the pursuit of efficient and sustainable broiler production practices.